The #BeastfromtheEast has meant lots of Norfolk businesses have had to close today but at Broadland Radiators we say “if life gives you snow – make snow angels”.

News and Case Studies

“Broadland Radiators have provided an excellent customer service by providing a technical expert to support our customer at their facility overseas.”

Proud to be able to share some glowing feedback after we sent our Engineering Manager to a client in Brazil on short notice to give them help and guidance on some installation issues they were having – I don’t think Roly objected too much about the sunshine!

The team at Broadland Radiators would like to thank all our customers and suppliers for the support you have given us during the last 12 months. We hope you have a Merry Christmas and a Happy, Healthy and Prosperous New Year.

Christmas cards are a tradition that span back many years,

Sent full of Christmas warmth to those we hold most dear.

But tradition is not our strong point and we would like to say,

We wont be sending Christmas cards as they only get thrown away.

Instead of buying cards and stamps and for your clarity,

We will make a cash donation instead to a worthwhile charity.

This year, Broadland Radiators will be making a donation to The Helping Harry Trust – a great cause that will put the money to really good use. https://www.facebook.com/thehelpingharrytrust/

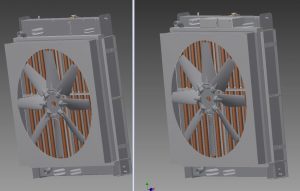

Full refurbishment completed on this unit for one of our valued Aberdeen clients. They sent us a “non-Broadland” radiator for a clean up and to modify to make it suit their installation better. New tanks with better mounting feet and additional sockets fitted whilst ensuring all connections, etc, fit within their existing setup – one very happy customer.

Broadland Radiators design, engineer and manufacture quality bespoke cooling systems used in a variety of applications.

One of our valued clients had a slight issue with room in their Genset application and asked if we could help. In the next 72 hours we re-ran calculations, redesigned the cooler, collected from customer, modified and rebuilt with new bespoke-made tanks, returned to customer and it was back in their package.

Customer said – “Chris, I looked into our final assembly shop yesterday morning and… awesome! The revised C9 radiator was back, installed and all piped up. Looks great! Thank you for putting this together for us on so short a timescale.”

Broadland Radiators design, engineer and manufacture quality bespoke cooling systems used in a variety of applications.

Really pleased to confirm another order received from a new contact made at OE2017 – the hard work beginning to pay off!

Broadland Radiators design, engineer and manufacture quality bespoke cooling systems used in a variety of applications.

Final day of #OE17 .

We have had a great exhibition and met lots of lovely people.

Our ‘can you keep your cool’ challenge is still up for grabs so make sure you pop along and see us today!

The health and safety of our colleagues remains one of our top priorities so we are pleased to mark the occasion of 3 years without an accident with new t-shirts and hats for everyone. Here is Sheryl looking ever so pleased to model her new t-shirt – well done to all the team, keep up the great work.

Preparations for our stand at the exhibition are taking shape and the batak competition looks like being great fun…

If you are visiting the exhibition, come and see us on stand 3D141, and why not have a go at our game to win the top prize!

We don’t just ‘say’ we work with our suppliers….we really do! Elmdale Welding And Engineering Supplies ltd ESAB Europe

At Broadland Radiators and Heat Exchangers we pride ourselves on producing products of only the very highest quality. We achieve this by truly collaborating with our fantastic suppliers.

One such example of this would be when Elmdale Welding asked if they could bring the ESAB demo bus to our yard to share some of their new products with us and other customers in the Anglia area.

Happy to help one of our favourite suppliers, here is Jamie Marshal of Broadland Radiators and Heat Exchangers Works Manager sharing a moment with Peter Elms, Managing Director of Elmdale Welding & Engineering Supplies Ltd to discuss some of the goodies on board.

The demo bus was a great success, lots of visitors and increased exposure for both our companies.